港虹產品詳情

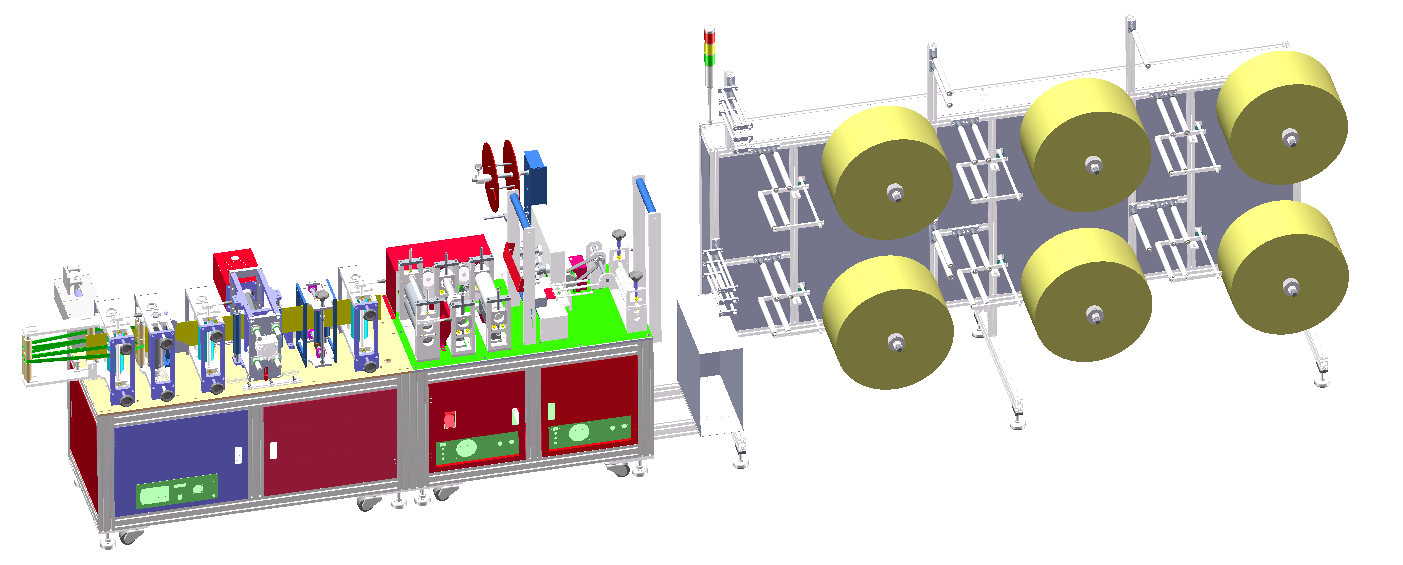

產品描述

|

|

|

Serial number |

Part Name |

Quantity |

Remarks |

|

|

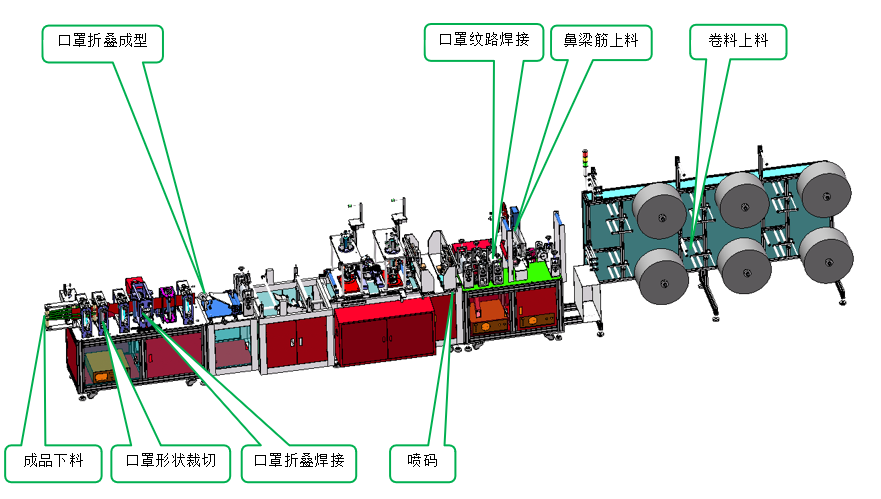

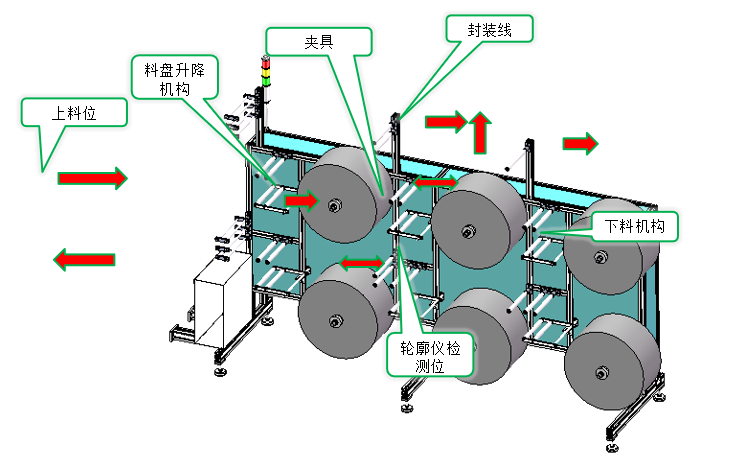

1 |

Water filter cloth/meltblown cloth/absorbent layer unwinding mechanism |

6 set |

Market purchase |

|

|

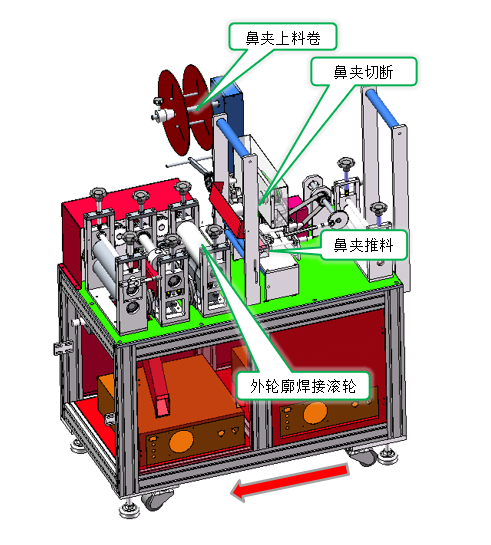

2 |

Nose unwinding mechanism |

1 set |

Market purchase |

|

|

3 |

Nose bridge drive and cutting mechanism |

1 set |

Market purchase |

|

|

4 |

Roll welding edge sealing mechanism |

1 set |

Market purchase |

|

|

5 |

Cloth drive mechanism |

1 set |

Market purchase |

|

|

6 |

Feeding mechanism |

1 set |

Market purchase |

|

|

7 |

Operating system |

1 set |

Ganghong |

|

|

8 |

Operation panel |

1 set |

Ganghong |

|

|

9 |

Hand-held welding machine |

1 set |

Optional, used for fabric tape |

|

|

10 |

Earband welding machine mechanism |

2 set |

Optional, offline operation |

|

如果您有任何疑問,請隨時與我們聯系

江陰港虹包裝機械有限公司

港虹專業從事各類包裝機械的研發、銷售、制造與售后服務。

全景工廠

阿里巴巴商城

官網網站

Copyright ? 2022 江陰港虹包裝機械有限公司